VCS7027-10

VCS7027-10On our website you will find a part of our offered product line. Is your desired product not listed? Then ask for the possibilities!

This equipment is used in case fast temperature variations shall be simulated. This equipment is also well suited for experiments where a lot of power is dissipated inside the test volume.

This thermal stress chamber is ideal for performing thermal stress tests on all sorts of materials because of the possibility of rapid temperature variations (HAST tests) and this in a large volume of 270 L. A typical application is the acceleration of ageing processes, for example, adhesive bonding, solder joints, composite materials, etc.

GENERAL PROPERTIES:

Test space volume:

270 liters (W x D x H) = 580mm x 620mm x 750mm

Schedules:

Up to 8 grids used in the test room with a maximum load of 30kg per grid and a maximum total load of 80kg.

Maximum load on the floor of the test room: 60kg.

Door with window which allows the samples to observe during a test without opening the chamber. This can be useful to a screen that is part of the test piece to read.

A flange (right side): Ø125mm

A flange (left side): Ø50mm

TEMPERATURE TESTS:

Temperature Range: -70 ° C to +180 ° C

Temperature change according to IEC60068-3-5:

heating: 10.0 ° K / min

cooling: 14.5 ° K / min

For the exact cooling - and heating curves, see Figure

CLIMATIC TESTS:

Temperature deviation in time: + / - 0.3 ° C to + / - 0.8 ° C

Temperature deviation in space: + / - 0.5 ° C to + / - 2.0 ° C

Heat Compensation: 6000W @ 20 ° C / 6000W @ -20 ° C

Temperature Range: 10 ° C to +95 ° C

Temperature deviation in time: + / - 0.1 ° C to + / - 0.5 ° C

Temperature deviation in space: + / - 0.5 ° C to + / - 1.0 ° C

Humidity Range: 10% to 95% rh

see curve

A - Test Room Temperature

B - Relative Humidity

Heat Compensation: 400W in the range of 25 ° C to +95 ° C

at a relative humidity up to 90%

Sensor: psychrometric moisture probe

CONNECTIONS:

Power: AC 400V 3/N/PE + / -10% 50Hz AC 230V OR 3/PE + / -10% 50Hz

Nominal power: about 14kW

Provide safety fuse: 32A

Data Interface: RS-232 and Ethernet connection for remote operation and monitoring through the SIMPATI software. The full operation of the unit and the registration of all data can be done through this interface.

PARTICULARS:

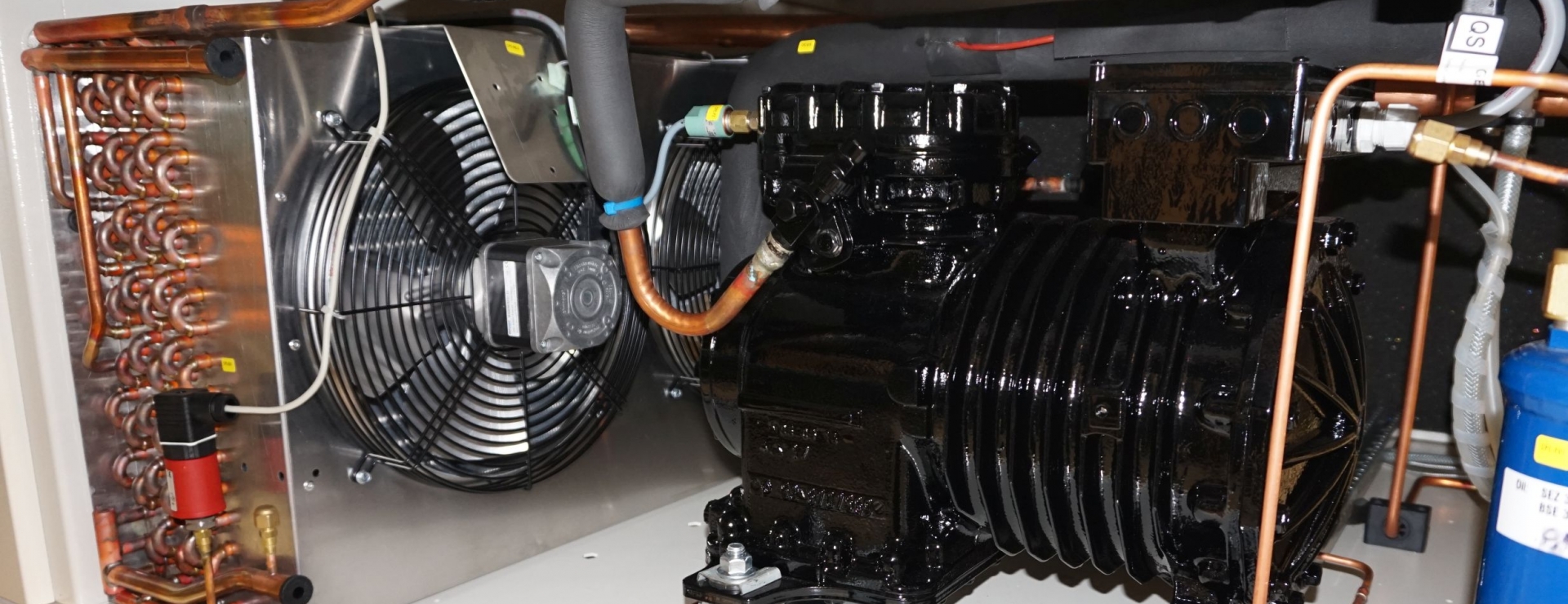

An air-cooled condenser is also part of the equipment. This is used for the second stage in the cooling circuit. The condenser is connected to the thermal chamber by two flexible connections.

Intuitive and easy control of the chamber. Simple programming of individual test PROGRAMS € ™ s.

Programmable dehumidifier to prevent condensation on the test well to avoid

Protection of test well: Safe use of the room by means of two independent safety circuits: a thermal cut through the control software and a fully independent hardware temperature limiter.

Good test interfacing: 4 digital outputs for the test well on or off via potential free contacts (Maximum 24 VDC 0.5 A). 4 digital inputs for reading status lines coming from the test well (24 VDC 30mA max). A free temperature sensor (PT100) can be used at any place within the test area, or well on the test itself, to measure. All these signals / values may include temperature and humidity via the Ethernet interface of the test case are recorded.

Elimination of test items: Potential-free contact material especially for heat-emitting Test (Maximum 24 VDC 0.5 A)

TEST STANDARDS:

Cold

IEC 60068-2-1, Test A

IEC 60721-4

DIN 40046, Part 3, Test A

DIN 72300-4

ETS 300019-2

VG 95332, sheet 3

VG 95332, sheet 22

BS 2011, Part 2, Test A

MIL-STD-810, meth. 502

MIL-E-5272, part 4.2

Heat

IEC 60068-2-2, Test B

IEC 60721-4

DIN 40046, Part 4, Test B

DIN 72300-4

ETS 300019-2

VG 95210, meth. 108A

VG 95332, page 4

VG 95332, sheet 23

BS 2011, Part 2, Test B

MIL-STD-202 E, meth. 108A

MIL-STD-810 D, meth. 501

MIL-STD-883 C, meth. 1008

MIL-E-5272, part 4.1

Constant climates

IEC 60068-2-3, test Ca

IEC 60068-2-56

IEC 60068-2-66

IEC 60068-2-78

IEC 60721-4

DIN 40046, Part 2

DIN 40046, Part 5

DIN 50014

DIN 72300-4

ETS 300 019 -2

VG 95210, page 4, test103B

VG 95332, sheet 5

BS 2011, part 2, test Ca

MIL-STD-202, meth. 103B

Temperature Change

IEC 60068-2-14, test Nb

IEC 60721-4

DIN 40046, Part 14, Test Nb

DIN 72300-4

ETS 300019-2

BS 2011, Part 2.1, Test N

MIL-STD-331 A meth. 112.1

ECSS-Q-70-08A

ECSS-Q-70-038

Change Climates

IEC 60068-2-30, test Db, var.2

IEC 60068-2-38

IEC 60068-2-4, test D

IEC 60721-4

DIN 40046, Part 6

DIN 40046, Part 101

DIN 50016

DIN 72300-4

ETS 300019-2

MIL-STD-331 A meth. 105.1

MIL-STD-810, meth. 507

MIL-T-5422 E, Part 4.4

MIL-E-5272, part 4.4

Note: The temperature values listed in the standards are limited by the maximum and minimum temperatures in the test area, taking into account the size of the test well and any heat dissipation of the test well.

To improve water quality in testing standards required to maintain the option of cleaning the water "is necessary.